AIR STARTER

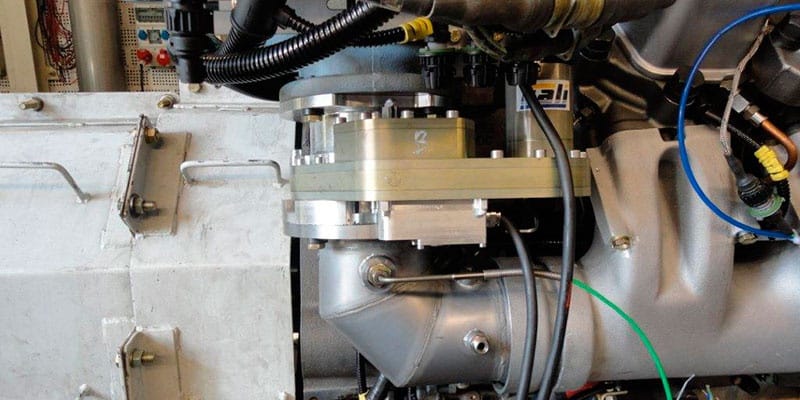

Compressed air starter are designed for use on internal combustion engines and gas turbines. For their size and weight, these starters are extremely powerful and also have high torque, high speed, low air consumption and minimal maintenance.

Gali starters can operate at a maximum pressure of 3/4 MPa (30/40 bar). The minimum working pressure depends on the installation situation.

Due to the fast response time and high speed of Gali starters, the engine immediately reaches its ignition speed, which increases starting efficiency.

Gali starters do not require external lubrication, therefore there is no need for an external lubrication pump. This means a clean and environmentally friendly installation which is easy to maintain.

They are resistant and highly resistant to moisture, salt air, vibration and extreme temperatures.

Gali starters are successfully used in a wide range of applications, e.g. marine engines (auxiliary and power take-offs) generators, in conventional and nuclear power plants, military, locomotives, offshore and mining, etc. Our starters are certified by Bureau Veritas, Lloyd's Register. Germanischer Lloyds & American Bureau of Shipping.

AIR STARTER

The first year of data revealed several interesting facts about building enclosure performance and building operation:

If you have any further questions, please do not hesitate to contact us at the following telephone number: +49 (0) 59 32 - 73 28 930

You can download an enquiry form here. Send it back to us at anfrage-galli@dmt-haren.de. Please enter "GALI product question" as the subject. For further information please contact us.

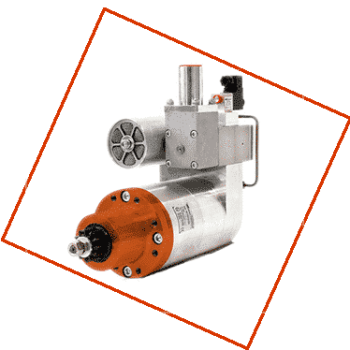

Request formPneumatic starters (colloquially: compressed air starters) are preferably used where electric starters cannot be used due to their (too low) power or other operating conditions. Compressed air is used as the energy source. Pinion starters are used on engines up to medium size, which are thus similar in design to electric starters. Large and largest diesel engines, for example in ships, are started by controlled injection into the combustion chambers.

Air starters as pinion starters are similar in design to electric starters, except that the electric starter motor is replaced by a pneumatic one. The compressed air supply must also be controlled (solenoid valve instead of relay) and the pinion engaged and disengaged.

In the oldest and simplest version of a pneumatic starter, only one cylinder head was equipped with a manually controlled air valve. First, the engine was set to just after TDC (top dead center) for this cylinder and the desired direction of rotation. After the other start preparations, the compressed air valve was opened briefly to start the engine rotating. Due to the flywheel mass, it continues to rotate and start. When the engine was running, the compressed air valve was occasionally opened manually so that combustion gases could flow back into the compressed air accumulator (via a purification stage, if necessary).

Later engines with compressed air starting had compressed air valves on several cylinders, which are controlled by an additional camshaft during the starting process. To enable starting in both directions of engine rotation, the starting camshaft can be “shifted,” and in four-stroke or controlled two-stroke engines, the normal camshaft can also be shifted. For starting itself, compressed air is applied to the manifold to the air valves, which open and close when the piston of the respective cylinder is in the correct position. As soon as the engine starts, the compressed air supply to the manifold is shut off and the compressed air valves remain closed.

Smaller engines with compressed air starting often have an attached air compressor, such as is required for the brake system of trucks. In the case of large engines, the necessary auxiliary units, including the compressed air generation, are driven by their own engines; on ocean-going vessels, several redundant systems are mandatory.